Electromagnetic Compatibility (EMC) Testing

Ensuring Electromagnetic Compatibility for Safety, Reliability and Global Market Access

Electromagnetic Compatibility (EMC) Testing

Ensuring Electromagnetic Compatibility for Safety, Reliability and Global Market Access

Electromagnetic Compatibility (EMC) Testing

DEKRA evaluates the applicable Electromagnetic Compatibility (EMC) requirements that an electronic device or component has in order to comply with national and international standards and requirements.

About EMC Testing

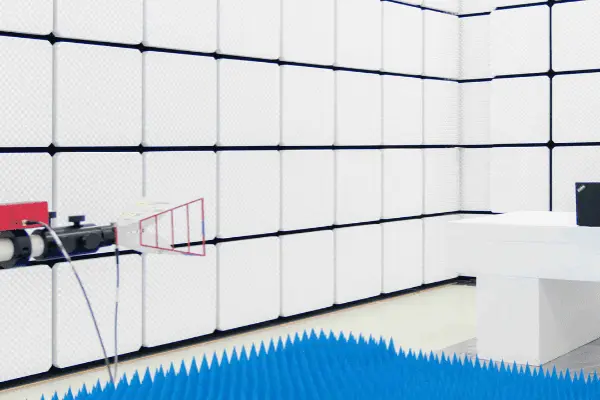

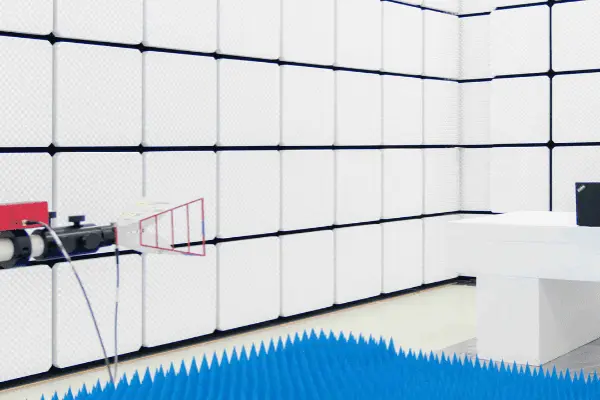

EMC testing ensures that products operate safely and reliably without interfering with other electronic devices or being affected by them. DEKRA conducts EMC testing for both emissions (radiated and conducted) and immunity (resistance to disturbances), in a controlled environment such as anechoic chambers and shielded rooms.

We provide EMC testing during the development phase (pre-compliance and debugging) as well as for final certification. Testing is customized for each device type, technology, and target market.

- Radiated and conducted emissions

- Radiated and conducted immunity

- Electrostatic Discharge (ESD)

- Electrical Transients Pulses (Automotive, Defence, Aerospace)

- Wireless coexistence

DEKRA is a EU Notified Body and Certification Body in several countries. Our EMC testing supports certification and regulatory requirements in:

- Europe (CE)

- USA (FCC)

- Canada (ISED)

- Japan (VCCI)

- Korea (KC)

- Taiwan (BSMI)

- Australia/New Zealand (RCM/RSM)

- South Africa (SABS)

- And many more

What is EMC testing, and why is it important?

What types of products require EMC testing?

What are the types of EMC tests?

Which EMC standards apply to my product?

Is EMC testing required globally?

What is the main difference in EMC testing requirements between Europe (CE), North America (FCC/ISED), Australia/New Zealand (RCM/RSM), Japan (VCCI), South Korea (KC) and Taiwan (BSMI)?

What is the EMC testing process?

What happens if my product fails EMC testing?

When should I start EMC testing?

Can I combine EMC testing with other services at DEKRA?